EcoCortec® the most advanced manufacturer of high-tech Vapor phase Corrosion Inhibiting

(VpCI®) films and bags in Europe is proudly announcing the latest innovation in its wide range of

flexible packaging products. The plant is now offering special custom VpCI® film covers/hoods

in various sizes and shapes.

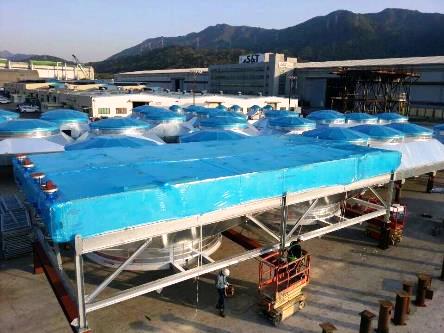

Air cooler (induced, forced type) preservation for long term outdoor storage and transportation with VpCI-126® High

Performance UV Film.

Cortec®'s premium shrink films VpCI®-126 and Milcorr® are now available as equipment covers

in small series. These high strength, high performance covers are designed to replace wooden

crates, containers, metal, plastic and wooden boxes. They are light weight thus reducing

transportation costs while being non- toxic and recyclable thus improving carbon footprint of

equipment manufacturers.

Air cooler (induced, forced type) preservation for long term outdoor storage and transportation with VpCI-126® High

Performance UV Film.

MilCorr® VpCI® Shrink Film and VpCI®-126 High Performance Film are latest technology heavy

duty films featuring Cortec®’s world renown multimetal (VpCI®) Vapor phase Corrosion

Inhibitors. They enable strong protection of surfaces against the most powerful elements of

nature. These films can be used to protect products for storage, preserving or shipment in safe

VpCI® environment. They combine the latest film technology with premium corrosion protection

for all multimetals. Both are safe for handling and economical to use by significantly reducing

labor for crating.

Cortec® MilCorr® VpCI® Shrink Film and VpCI®-126 High Performance Film covers/hoods provide a

top-notch universal protection system and maintain the integrity of the film itself as well as the parts

packaged within.

Metal parts packaged in MilCorr® or VpCI®-126 High Performance Film receive continuous

protection against salt air and humid environments, moisture, aggressive industrial atmospheres

and dissimilar metal corrosion. The VpCI®'s vaporize and condense to metal surfaces in the

enclosed package, reaching every area of the part, even hardest-to-reach interior surfaces. This

allows complete product protection during storage as well as during domestic and overseas

shipments virtually eliminating any rust claims. These high-tech covers and hoods replace

conventional rust preventatives such as oils and desiccants. They eliminate all the degreasing or

coating removal required in the past allowing customers money savings.;

Equipment protected with MilCorr® or VpCI®-126 Shrink Films can be used immediately without

need for cleaning or degreasing. These products are free of amines, nitrites, phosphates, halogens

and other toxic chemicals. VpCI® shrink films are offered printed with logos of equipment

producers at no extra charge providing brand and counterfeit protection as well as protection

against high winds, rain, snow, ice and sand storms. They are economical alternative to crating

therefore making it easy for equipment to cross customs check-ups without damaging the integrity

of the packaging.

Cortec®’s MilCorr® VpCI® Shrink Film and VpCI-126® High Performance Film conform to

military specification MIL-B-22019D, NACE Standard RP0487-2000 and are RoHS compliant.